Ethanol extraction is a process that has been around for a long time. That’s because ethyl alcohol is a natural product that has had many great advantages for companies. With the advent of newer technology and more energy-efficient equipment, there are more benefits available to the consumers.

This procedure is highly versatile, as it found its applications across many industries. Although most companies opted for other methods, such as hydrocarbon or CO2 extraction, ethanol is still the first choice. It’s especially popular among small-scale producers.

More information on ethanol check below:

https://www.chemicalsafetyfacts.org/ethanol/

Cosmetics, food and beverage, CBD, and all those businesses that use plant materials must process it. The chosen extraction method should pull out the best from the raw material. As ethyl alcohol is safe for human use and doesn’t need any specific storage conditions, many companies find it quite useful.

Mechanism of Action

Ethanol extraction machines work by using a continuous cycle of heating and cooling. The heat source is the burning of the ethyl alcohol obtained via the condenser at the bottom of the extractor. Cooling happens when water flows through the chilled lines coming out of the condenser coil. The cooled liquid is then pumped back into the extractor, where further processing takes place.

The maturation of the alcohol takes place in a secondary fermentation vessel. It contains layers of material that, when heated, allow the alcohol to split into gas and water. Water acts as a catalyst to turn gas into steam. Then, it will become liquid once it cools off within collection vessels.

Advantages of Ethanol Extraction Procedure

Ethanol extraction has many advantages over other similar methods. Some of its biggest advantages are that it’s better for the environment and safe for human use. It means this compound is also safe to handle and work with (in lab conditions).

Like any alcohol, ethyl is flammable. Yet, its action in contact with fire is quite predictable. It reduces the risk of fire or explosion, but only if this compound is stored properly. It doesn’t have to be under pressure and certain temperatures; only a well-sealed container is required.

Another good side of this solvent is that it’s renewable. Consumers (industries) can always get more of it. Ethanol, or at least most of it, can be used over and over again. After the extraction is complete, technicians can easily return this derivative to its original form.

Certain steps need to be taken, such as recovery and distillation of extracts. At some point, the recovery process will slow down, as ethyl alcohol has a high boiling point. That can be tricky in terms of power consumption.

Product Purity

A benefit that most buyers will appreciate (although they probably don’t have a clue about what ethanol has to do with it) is residue-free products. This solvent can remove about 90% of toxins from the final extract. These traces are harmful and can endanger soil, water, and, most importantly, human health.

Ethanol extraction and the machines required for this process have a special application in the CBD industry. The purity of the final product is especially important here, given the huge demand for quality hemp goods.

With the help of extractors, useful substances such as CBD and terpenes are extracted from the raw material. These machines will separate hemp biomass, too. Read about good and bad sides of this extraction method for cannabis products here.

Financial Benefits for Industries

What companies are most interested in are costs. The purchase price of ethanol is low, which contributes to high demand and widespread use. There are hints that this solvent will be even cheaper in the future once the market is fully regulated.

Once a particular law is enacted, some substances (such as butane and CO2) will have limited use. That will affect the rise in their prices, and this is not the case with ethyl alcohol. Market regulation will bring an excise tax refund. That will force extraction shops to lower the prices of this compound.

Reasons to Invest in Quality Equipment

There are several different ethanol extract machines on the market. All ethanol machines have the same basic principle, which is to boil off the ethanol and then cool it. This change should provoke a reaction with raw plant material. After ethanol treatment, it should release active components.

The cold solvent will purify the extract from unwanted residues. On the other hand, a warm ethanol procedure can provide a fuller plant profile. It means higher potency and purity of certain products. That’s especially beneficial for medications and CBD goods.

Extraction equipment can vary in price, depending on its size, capacity, and functions. There are ethanol extraction machines even for home use. These can be useful if you want to make home-made cosmetics or CBD oil.

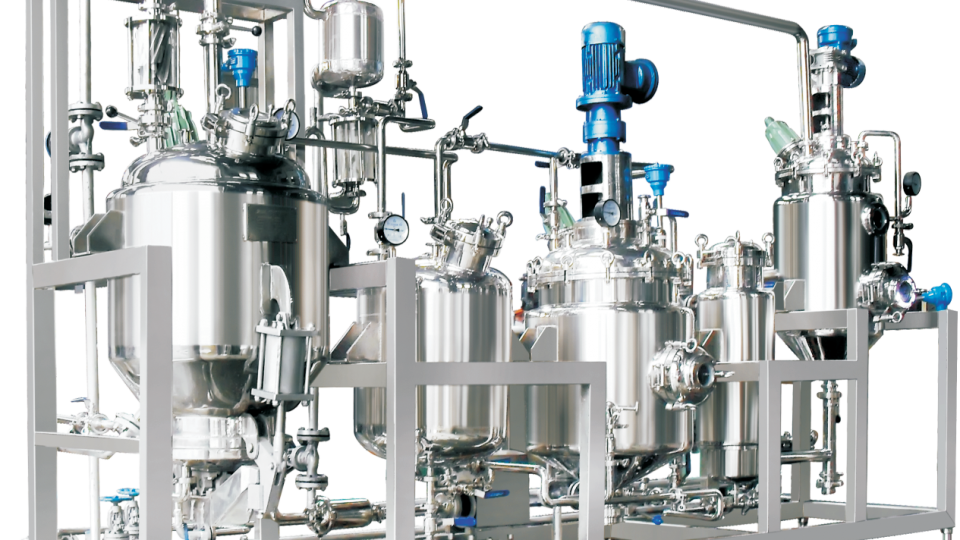

Larger models intended for industrial use will have several stages with different functions. They usually provide plants with an all-in-one extraction system. These circuits will serve for distillation, dehydration, etc. Special attention is paid to the solvent recovery part, which makes the whole extraction process even cheaper. Purified ethanol can be reused, so there is no need to buy more solvents.

Quality equipment has a great impact on the quality of the product itself. That is why extraction machines should always be bought from proven manufacturers. Whether you need this equipment for home use or industrial purposes, it pays to invest in machines from proven brands.

Leave a Reply